- #L298N STEPPER MOTOR DRIVER CONTROLLER BOARD MODULE MANUAL DRIVER#

- #L298N STEPPER MOTOR DRIVER CONTROLLER BOARD MODULE MANUAL MANUAL#

- #L298N STEPPER MOTOR DRIVER CONTROLLER BOARD MODULE MANUAL FULL#

This will result in the motors stopping slowly and naturally from friction. To remove power from the motors, simply set ENA=LOW for Motor A and ENB=LOW for Motor B. If your robot does not move in the expected direction, reverse the motor polarity by swapping the green screw terminals for Motor A + and – and/or Motor B + and. Note that “forward” and “backwards” refer to the direction of the motors themselves. The same method is used to control Motor B: set IN3=HIGH and IN4=LOW to o forward and set IN3=LOW and IN4=HIGH to go backwards. To make Motor A go backward set IN1=LOW and IN2=HIGH. To make Motor A go forward, set IN1=HIGH and IN2=LOW. Connect these pins to digital outputs on your robots microcontroller.

#L298N STEPPER MOTOR DRIVER CONTROLLER BOARD MODULE MANUAL DRIVER#

The direction that the motors turn is controlled using the IN1, IN2, IN3 and IN4 input pins on the motor driver board.

We recommend always using a PWM duty cycle of 90% or less. The longer the PWM duty cycle is, the faster the motor will turn. By using PWM, you are turning power on and off very quickly to adjust the speed of the motor. When these pins are HIGH, power is output to the motor. The ENA pin controls Motor A and the ENB pin controls Motor B. The speed of the motors can be adjusted by connecting PWM outputs from your robot’s microcontroller to the ENA and ENB input pins on the motor driver board. Leave the jumper connected when not using current sense.

To use the current sense feature, remove the jumpers and attach to the header pins. Note: The CSA and CSB current sense feature is disabled when the jumpers are present. Header pin assignmentsĮnable Motor A input pin IN2 pull-up resistor (10K)Įnable Motor B input pin IN3 pull-up resistor (10K)Įnable Motor B input pin IN4 pull-up resistor (10K) Do not enable the onboard 5V regulator if you are supplying more than 16V to motors on pin 3 or the regulator will burn out. Otherwise you must input 5V regulated power at pin 5 so that the circuit can operate properly. Note that the 5V regulated power on pin 5 above is an output when the 5V_EN jumper is in place. Hardware Details Screw terminal pin assignments Below are the sample sketch to test and drive the motors with PWM (Pulse with Modulation). Controlling the Speed of the motor you need to used the PWM(Pulse with Modulation) signal from the digital pin connected to the Arduino enabled pin can. The motor direction is controlled by sending a HIGH or LOW signal to the driver on each channel.įor example Motor A1 and A2 a HIGH to IN1 and LOW to IN2 will cause it to turn in one direction and LOW and HIGH will cause it to turn in other direction. Then connect Digital 10 to module pin PWM 1 you need to remove the jumper fist plug Digital 5 to module PWM 2. PWM pins are denoted by symbol (~) next to the pin Number.Ĭonnect the Arduino Digital Pins to the L298n Module see our example diagram below, in the diagram we have 4 and 2 DC motors so digital pins D9 D8, D7 and D6 will be connected to IN1, IN2, IN3, and IN4. 2 of the pins you need to used PWM(Pulse with Modulation) pins.

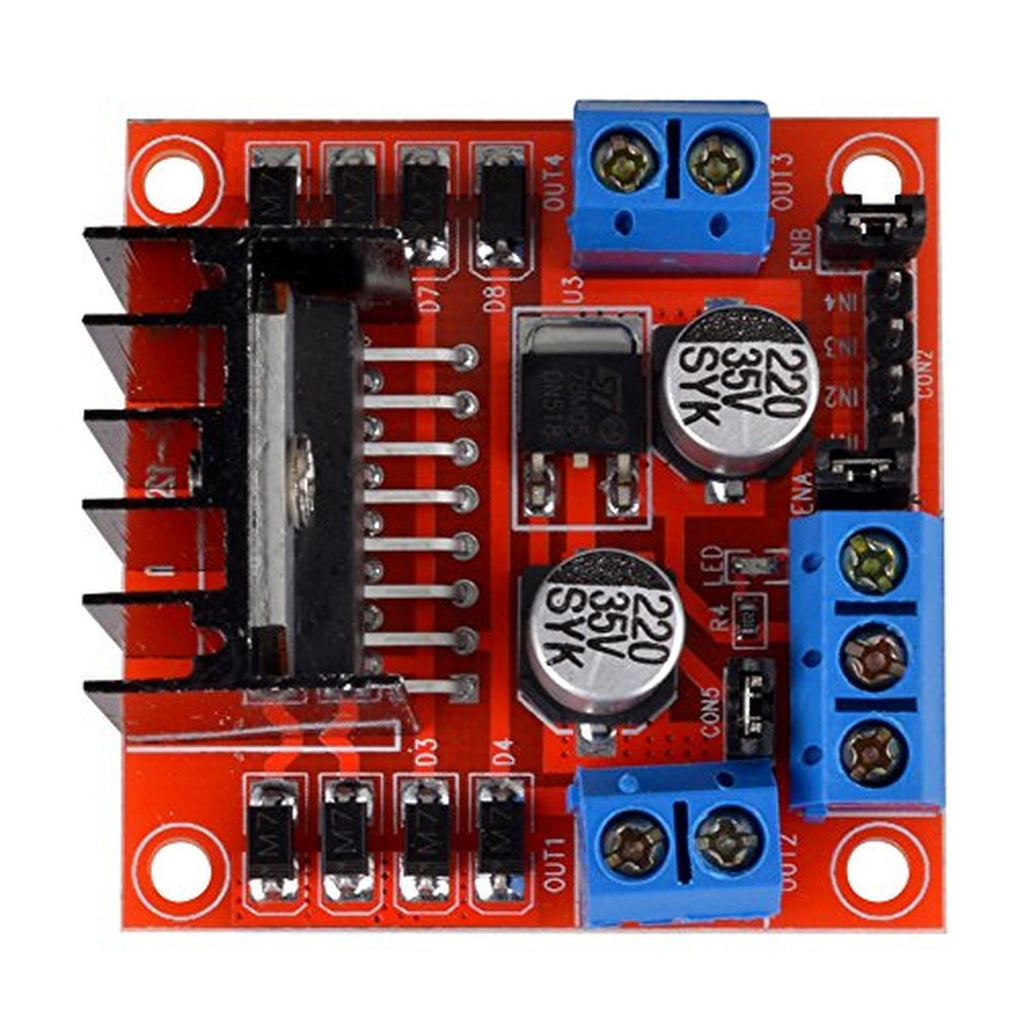

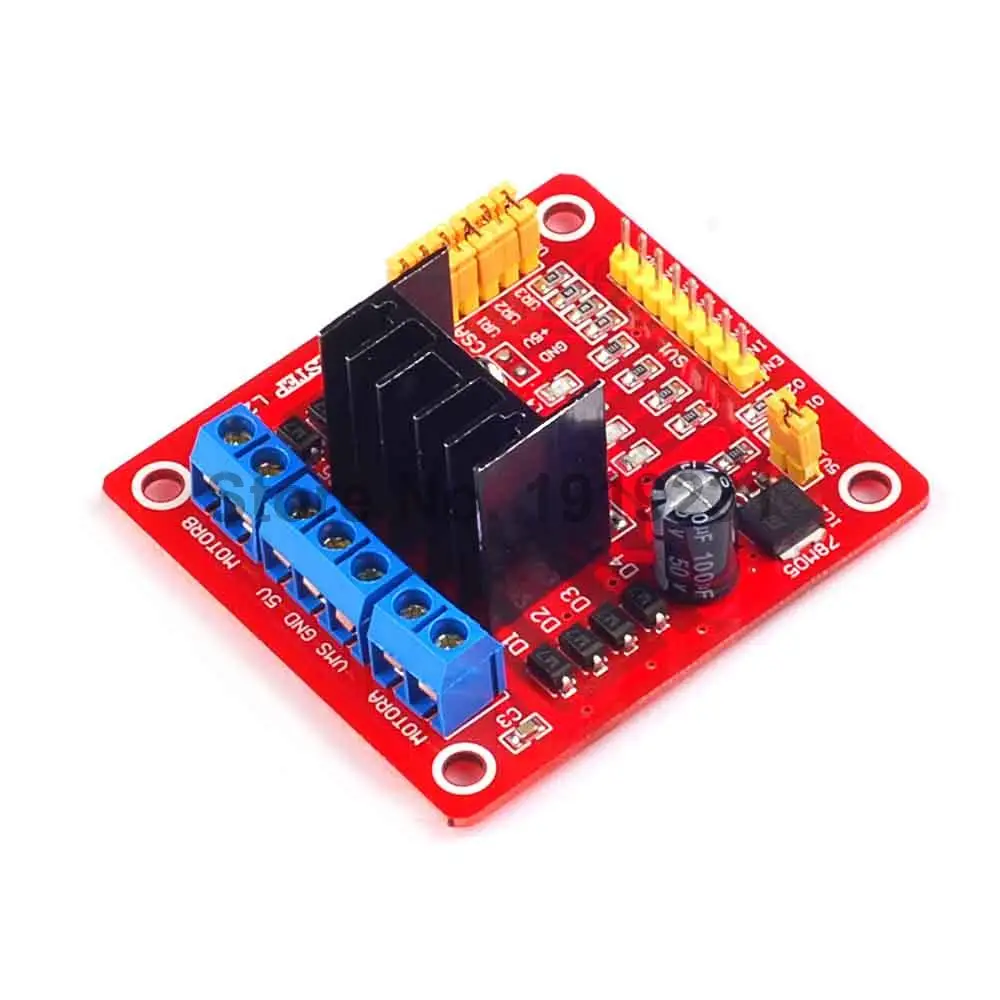

We need to connect 6 digital output pins on your Arduino. If your using two motors for a robot you need to ensure that the polarity of the motors is the same on both outputs, otherwise you need to swap them when you set the motors to forward and backward. Wiring and controlling a DC motor is quite easy, you just need to connect each motor to A1-A2, B3-B4 or Out 1-2, Out 3-4 It depends how the L298n board configuration. If you want to build your own, see the schematic diagram below. There are many model of l298n boards in the market, see the photo below for examples. Control Logic: Standard TTL Logic Level.

#L298N STEPPER MOTOR DRIVER CONTROLLER BOARD MODULE MANUAL MANUAL#

It can also be interfaced with simple manual switches, TTL Logic gates and relays. It is excellent for robotics applications and well fit to a microcontroller. This module has ease to connect and drive a dc motor or stepper motor allows you to easily and intently control two motor up to 2A each in both direction or one stepper motor. Additional supply input is provided so that the logic works at lower voltage. The emitters of the lower transistors of each bridge are connected together and the corresponding external terminal can be use for the connection of external sensing resistor. Two enabled inputs are provided to enable or disable the device independently of the input signals.

#L298N STEPPER MOTOR DRIVER CONTROLLER BOARD MODULE MANUAL FULL#

It is a high voltage and high current full dual bridge driver designed to accept standard TTL logic level and drive inductive loads such as relays, solenoids and DC stepper motor. The l298 is an integrated monolithic circuit in a 15 lead multi-watt and power S020 package. The L298 H Bridge is base on l298 Chip manufacture by ST Semiconductor.

0 kommentar(er)

0 kommentar(er)